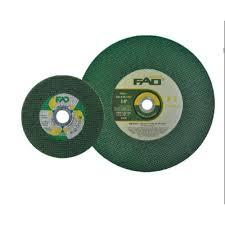

FAD Granite Cutting Blade ( Hot Pressed)

80 INR

Product Details:

- Operation Type Dry and Wet Cutting

- Cutting Speed High Speed

- Tool Type Diamond Saw Blade

- Cutting Accuracy High Precision

- Operate Method Mechanical

- Hardness Optimized for Stone Cutting

- Cutting Force High

- Click to View more

X

FAD Granite Cutting Blade ( Hot Pressed) Price And Quantity

- 80 INR

- 80.00 - 100.00 INR

- 200 Piece

FAD Granite Cutting Blade ( Hot Pressed) Product Specifications

- Others

- Long Life, Fast Cutting, Hot Pressed, Durable, High Efficiency

- High

- Suitable for Granite

- Granite Cutting Blade

- Diamond Segment

- 110 mm (common size); Available in multiple sizes

- Granite Cutting Machine / Angle Grinder

- Round

- Diamond Saw Blade

- Mechanical

- High Precision

- Dry and Wet Cutting

- Hot Pressed

- High Speed

- Optimized for Stone Cutting

FAD Granite Cutting Blade ( Hot Pressed) Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1000-10000 Piece Per Week

- 1-2 Days

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- All India

Product Description

FAD Granite Cutting Blade (Hot Pressed) is largely suited for the processing of many types of stone, such as granite, concrete, marble, and other special-formed stone. It can be used well for the rough machining and correct the contour of uneven small stone. This is a sharp and stable blade, offered with cutting edge corners. This is known well for its neat, precise and high cutting efficiency. FAD Granite Cutting Blade (Hot Pressed) can be made well through the process of sintering as well as cold-pressing methods. It is apt to be used for both dry and wet.

Precision Engineered for Stone Cutting

The FAD Granite Cutting Blade is meticulously crafted using the hot pressed process, resulting in a strong diamond-bonded segment that provides superior hardness. With a segment height of 7-10 mm and a diameter of 110 mm (other sizes available), the blade ensures highly accurate and smooth cuts on granite, marble, stone, and tiles, minimizing chipping and delivering professional-grade results.

Highly Versatile for Professional Settings

Designed for industrial use, this granite cutting blade is compatible with various granite cutting machines and angle grinders. It can be used for both wet and dry cutting processes, offering flexibility across different operational environments. The blades robust construction and long-life durability ensure it withstands frequent, heavy-duty use, making it a reliable choice for professionals.

Optimized Cutting Performance

Thanks to its diamond-coated segments and high-speed capabilities, this blade ensures fast and efficient cutting. It exhibits low noise and excellent wear resistance, enabling smooth operations and reducing the need for frequent replacements. Its high cutting force and optimized hardness make it ideal for tough stone-cutting jobs, maximizing productivity while maintaining safety and precision.

FAQs of FAD Granite Cutting Blade ( Hot Pressed):

Q: How should the FAD Granite Cutting Blade be used for optimal performance?

A: To achieve optimal results, mount the blade securely on a compatible granite cutting machine or angle grinder. The blade supports both dry and wet cutting methods; however, using water during cutting can further enhance cooling and lifespan, although the blade is designed to perform efficiently even in dry conditions.Q: What materials can this granite cutting blade handle?

A: This blade is specifically designed for high-precision cutting of granite, marble, stone, and tiles. Its diamond-bonded segment and robust construction enable it to perform smoothly across a wide range of natural and engineered stones.Q: When is it recommended to use wet cutting with this blade?

A: Wet cutting is suggested when working with thicker or denser materials, or during extended cutting sessions, as water assists in cooling, reduces dust, and extends blade life. However, for convenience or where water use is not possible, dry cutting is also highly effective thanks to the blades hot pressed, wear-resistant design.Q: Where is this granite cutting blade commonly used?

A: The FAD Granite Cutting Blade is widely used in stone fabrication workshops, construction sites, tile installation projects, and countertop manufacturing units throughout India and beyond. Its compatibility with various cutting machines makes it suitable for both on-site and factory settings.Q: What benefits does the diamond-bonded segment offer?

A: The diamond-bonded segment delivers superior cutting efficiency, excellent wear resistance, and long operational life. This ensures high cutting speed, reduced downtime, and greater value over time, especially when handling hard stones like granite.Q: How does the segment thickness and height contribute to cutting capacity?

A: A segment thickness of approximately 2.0 mm and a height of 7-10 mm provide a balanced combination of durability and sharpness. This allows for precise cuts with minimal material wastage while supporting extended use before requiring blade replacement.Q: What is the process behind the hot pressed manufacturing of this blade?

A: The hot pressed process involves molding and sintering the diamond and metal powder mixture at high temperatures, resulting in a dense, robust segment bond. This technique enhances the blades mechanical strength, wear resistance, and cutting efficiency, making it suitable for intensive professional applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free